Researchers from FEEC Verified the Parameters of the Innovative DROVEN Heater

A team from the Department of Theoretical and Experimental Electrical Engineering participated in the numerical modeling of the DROVEN system, which brings technology from the aviation industry into water heating and achieves up to ten times higher heat transfer efficiency than competing heaters.

Tomáš Kříž (left) and Jan Mikulka, Department of Theoretical and Experimental Electrical Engineering, FEEC. | Author: Jakub Rozboud

The DROVEN system, now commercially offered by ENBRA, DROVEN HEATING, and other heating technology manufacturers, underwent a thorough numerical CFD (Computational Fluid Dynamics) analysis at the Faculty of Electrical Engineering and Communication (FEEC). Researchers from the Department of Theoretical and Experimental Electrical Engineering in collaboration with ENBRA, focused on identifying the technological and operational limits of this patented heating element.

Comprehensive Numerical Modeling

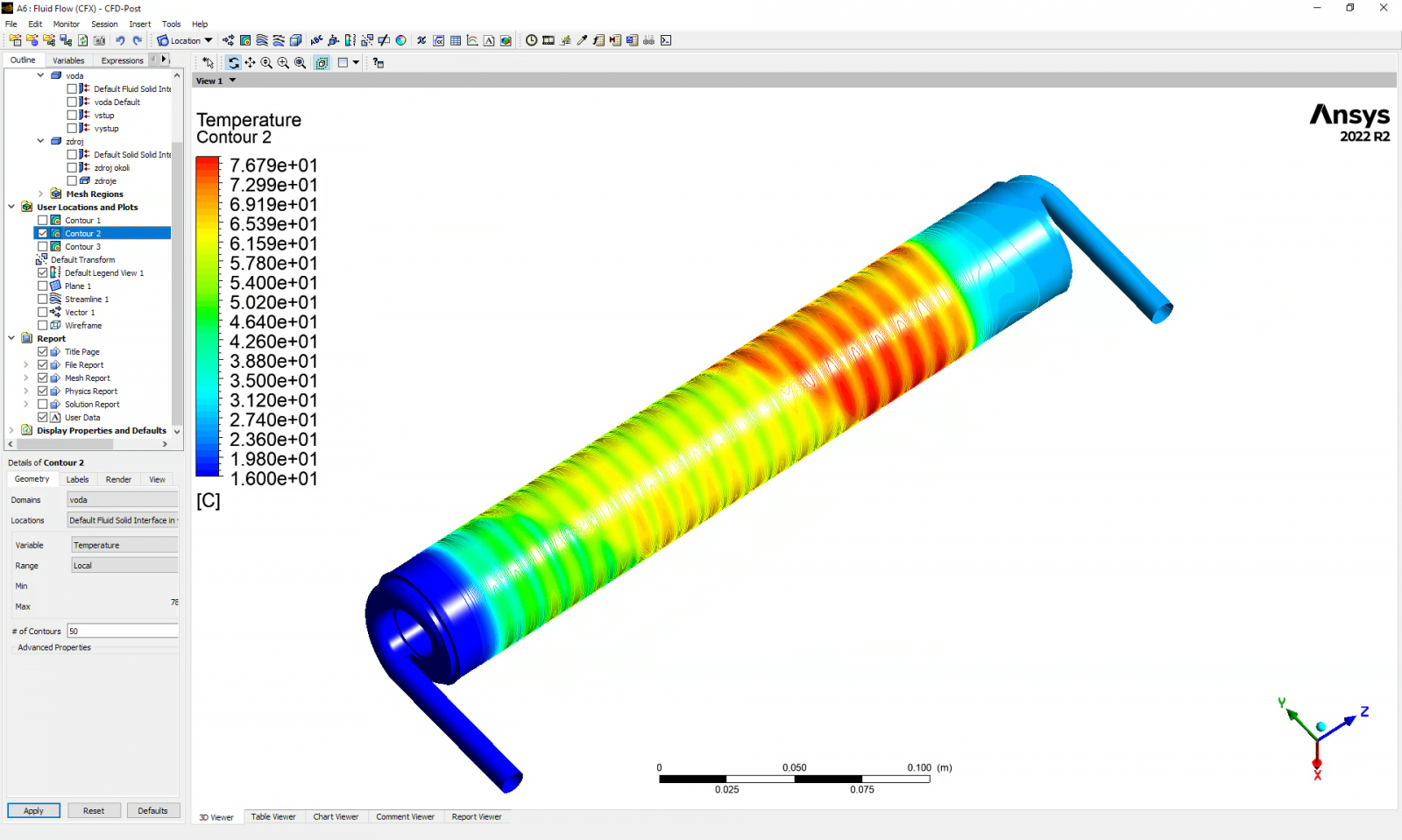

“Our goal was to identify the technological and operational limits of the DROVEN heating element through numerical modeling,” explains Jan Mikulka, head of the department. The research team focused on four key areas: determining heat transfer under various power levels, establishing the minimum flow rate needed to maintain turbulent flow, analyzing the influence of water temperature on flow, and examining dynamic pressure on the heat exchange surface.

“This unique research made it possible to determine the minimum water flow rate required to maintain spiral turbulent flow, which is essential for maximizing heat transfer from the plate heater,” adds Tomáš Kříž from the departmnet, who conducted the numerical simulations and measurements.

The results showed that a flow rate of 5 liters per minute is the minimum required to ensure effective heat transfer within the heater. Despite its compact dimensions (340 × 70 mm, 2 kg), the system can operate with a power output of up to 12 kW, heating flowing water by up to 30°C at a flow rate of 4 liters per minute.

Verification of Spiral Turbulent Flow

Numerical modeling confirmed that spiral turbulent flow is indeed maintained throughout the heater’s volume. “It was found that flow velocity decreases toward the outlet, while the flow retains its helical shape under optimized heater configuration,” adds Mikulka. The analysis demonstrated that spiral turbulent flow remains stable across the entire operating temperature range for domestic hot water — from 20°C to 70°C.

The system’s extremely fast heating speed is evident from the results — water can be heated from near-zero temperature to 17°C in just five seconds. The deviation between simulations and actual measurements did not exceed 2.5%, confirming the accuracy of the numerical model.

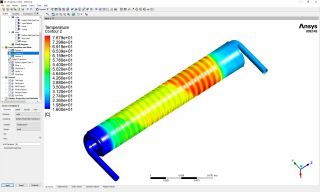

Heater visualization during simulation. | Author: Jakub Rozboud

Contribution to Energy Efficiency

The system is ideally designed for combination with photovoltaic panels and other renewable energy sources. It can heat only the amount of water being drawn, minimizing thermal losses from storage tanks. The technology received the AOVT Grand Prix 2022 (award from the Water – Heating Trade Association) for innovation in the field.

The results of the numerical modeling contribute to achieving the EU’s climate goals and support the development of technologies for more efficient use of renewable energy sources.

The outputs are part of the project CZ.01.1.02/0.0/0.0/19_262/0020065 "Vývoj zařízení pro ohřev kapaliny" (Development of a Liquid Heating Device

| Responsible person | Ing. Zdeňka Koubová |

|---|---|

| Date of publication |