The Invisible Power of Chips: Modern Semiconductors Communicate and Pave the Way for an Intelligent Future

Today’s world runs on chips. With their help, we can heat food in a microwave, measure our heart rate during exercise, or rely on car safety systems. These tiny semiconductors are becoming increasingly advanced and can even communicate with each other. Their development is also dynamically progressing in the Czech Republic, where new study programs are opening and companies are showing growing interest in manufacturing. In the following interview, the world of chips is explained by Associate Professor Lukáš Fujcik from the Faculty of Electrical Engineering and Communication Technologies at Brno University of Technology (BUT).

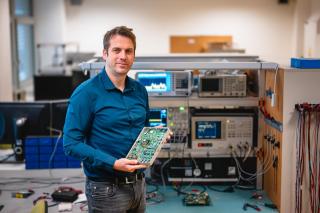

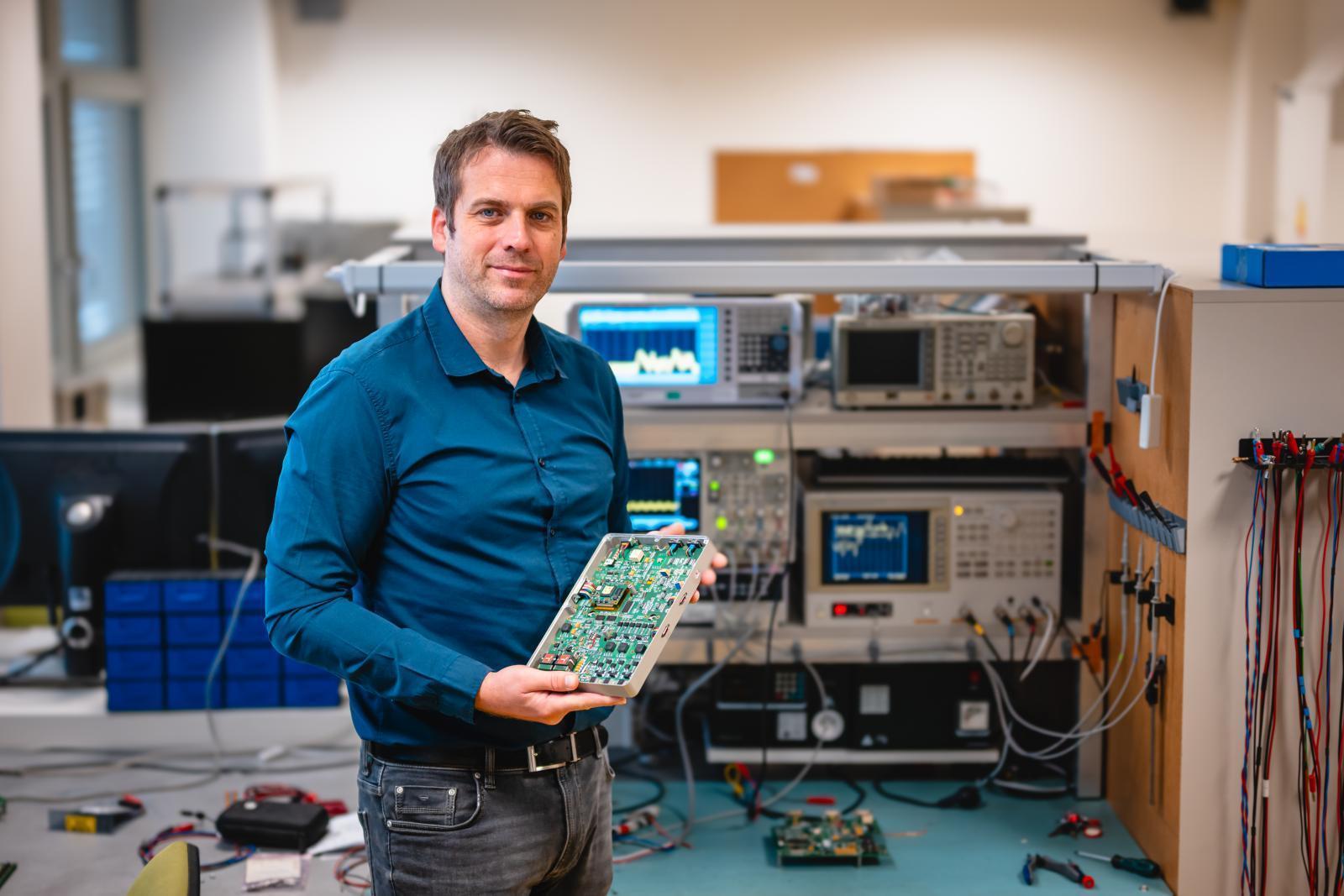

Lukáš Fujcik at Brno University of Technology. | Author: Jakub Brandejs

How can we imagine a chip?

Imagine a small plate, usually smaller than a pinky nail. It looks ordinary—a little black square with tiny legs—but inside hides a miniature world. There are millions of “micro-switches” controlling what the device should do. The chip acts as the brain of the device. It controls, monitors, calculates, and communicates. We usually don’t see it, but modern technology wouldn’t function without it.

What are chips made of, and where do the necessary raw materials come from?

The basic material is silicon—the same element found in ordinary sand. But it must be perfectly pure. In addition to silicon, advanced materials such as silicon carbide or gallium nitride are increasingly used, especially in high-performance chips. These raw materials are mined worldwide, for example in China, the USA, or Australia, and shipped to locations where chips are designed and manufactured. Europe aims to become more self-sufficient in this regard so that it is not dependent on supplies from Asia during crises.

Is chip manufacturing complicated, or is it automated machine work or simple manual labor?

Chip production is one of the most complex tasks humanity has accomplished. It takes place in extremely clean rooms with less dust than an operating theater. Some parts of a chip are thinner than a human hair. Most of the production is automated, but top engineers monitor and control everything. It’s not an assembly line—it’s more like a scientific and technological orchestra.

How long does it take to make a complete semiconductor chip?

Designing a chip can take a year or longer. The actual production of a single “wafer” takes several weeks, followed by testing, cutting, and packaging. It’s not fast, but that’s why the results are so reliable. It’s like making a watch the size of a grain of dust.

What can chips do?

Some monitor temperature, others control an airplane or a car camera. They can measure, calculate, react, collect data, and make decisions. You’ll find them in smartphones, power plants, and satellites. Even in a smart washing machine that detects how much laundry you have and decides how much water it needs. Chips are increasingly communicating with each other and making autonomous decisions, for example in cars or smart homes.

Everyone knows chips are in cars or mobile phones, but where else are they?

They are everywhere: in payment cards, electric toothbrushes, washing machines, smartwatches, and traffic lights. In cameras that recognize faces and in thermostats that save energy at home. Even in a light bulb that dims itself when you fall asleep.

Are there products where you wouldn’t expect chips, but they are still there?

Absolutely! For example, smart sneakers that measure your walking and step technique, or a flower pot that tells you via your phone when to water the plant. In modern hospitals, there are even bandages that monitor wound healing. Today, chips help in areas where a few years ago we wouldn’t even imagine them.

Are there devices that don’t yet have chips but could in the future?

Yes, for example textiles that monitor health or building materials with sensors for temperature and humidity. Even food packaging with a chip that can tell if your yogurt has spoiled. We are heading toward a time when “smart” will apply to things that were once completely ordinary.

Are chips manufactured in the Czech Republic?

Yes! They are produced, for example, in Rožnov or Prague, but the Czech Republic’s main strength is in chip design. Brno, Prague, and Pilsen are cities where chips for space, medicine, automotive, and energy applications are designed. With the new national semiconductor strategy, much more is planned. The Czech Republic wants to be visible on Europe’s chip map. According to the strategy, the chip sector should triple by 2029.

Is it a well-paid profession? How much does a chip cost?

Definitely! People in this field have excellent salaries due to how demanding and important the work is. As for chip prices, some cost just a few crowns, others thousands—for example, high-performance graphics chips for computers or specialized AI chips. The price depends on the chip’s capabilities, the target technology, and production volume.

How can the Czech Republic ensure sufficient manufacturing capacity?

We need to train a new generation of experts—designers, technicians, and engineers. New study programs help with this. For example, BUT in Brno opened a new program this academic year: “Chip Design and Modern Semiconductor Technologies.” The Czech Republic is also involved in the significant European project Chips of Europe, connecting schools, companies, and students across Europe to nurture future semiconductor talents. Support for research, simplifying the arrival of skilled professionals from abroad, and building infrastructure for new companies are also important. The goal is to have over 9,000 people in the field—three times more than today.

Is there interest in studying semiconductors?

Yes, and it’s growing. Students realize it’s a field with a future. They can contribute to developing technologies for cars, space, or healthcare, with the certainty that their work will remain valuable for decades. This is very appealing to young people.

What is the employability of graduates in this field?

Excellent. Companies from the Czech Republic and abroad are already interested in them during their studies. Whether they want to design chips, test them, or program them, the doors are open. Industry, research, development, start-ups, space technologies—there are countless opportunities. And demand will only continue to grow.

Text by Nikola Zámečníková

| Responsible person | Ing. Zdeňka Koubová |

|---|---|

| Date of publication |